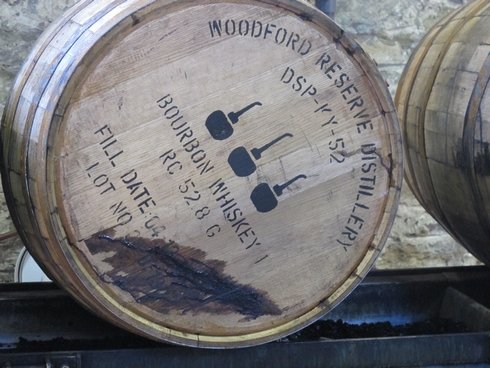

The most sought-after bourbon in the world, Pappy Van Winkle 23-year-old, begins life as 53 gallons of new-make whiskey at 114 proof.

The most sought-after bourbon in the world, Pappy Van Winkle 23-year-old, begins life as 53 gallons of new-make whiskey at 114 proof.

What's left in the barrel after 23 years is a mere 14 gallons of bourbon at around 135-140 proof. What makes it into the bottle is even less.

So I decided to run the numbers on how much Pappy Van Winkle is left in the barrel every year after evaporation (aka the "angel's share").

According to Harlen Wheately, Master Distiller at Buffalo Trace, the angel's share is 10 percent for the first year (because whiskey is absorbing into the wood of barrel as well as evaporating), then 4 percent for the next 8 years after that, then around 3 percent per year after that.

(They store the future Pappy in barrels in the parts of the warehouse with the least evaporation as they know they want it to age for a very long time.)

| Pappy Van Winkle 23 Countdown | |||

| Year | Angel's Share (Percent) | Math | Total |

| 1 | 0.1 | 53 -(.10)*53 | 47.7 |

| 2 | 0.04 | =D3-(D3*B4) | 45.792 |

| 3 | 0.04 | =D4-(D4*B5) | 43.96032 |

| 4 | 0.04 | =D5-(D5*B6) | 42.2019072 |

| 5 | 0.04 | =D6-(D6*B7) | 40.513830912 |

| 6 | 0.04 | =D7-(D7*B8) | 38.89327767552 |

| 7 | 0.04 | =D8-(D8*B9) | 37.3375465684992 |

| 8 | 0.04 | =D9-(D9*B10) | 35.8440447057592 |

| 9 | 0.04 | =D10-(D10*B11) | 34.4102829175289 |

| 10 | 0.03 | =D11-(D11*B12) | 33.377974430003 |

| 11 | 0.03 | =D12-(D12*B13) | 32.3766351971029 |

| 12 | 0.03 | =D13-(D13*B14) | 31.4053361411898 |

| 13 | 0.03 | =D14-(D14*B15) | 30.4631760569541 |

| 14 | 0.03 | =D15-(D15*B16) | 29.5492807752455 |

| 15 | 0.03 | =D16-(D16*B17) | 28.6628023519881 |

| 16 | 0.03 | =D17-(D17*B18) | 27.8029182814285 |

| 17 | 0.03 | =D18-(D18*B19) | 26.9688307329856 |

| 18 | 0.03 | =D19-(D19*B20) | 26.1597658109961 |

| 19 | 0.03 | =D20-(D20*B21) | 25.3749728366662 |

| 20 | 0.03 | =D21-(D21*B22) | 24.6137236515662 |

| 21 | 0.03 | =D22-(D22*B23) | 23.8753119420192 |

| 22 | 0.03 | =D23-(D23*B24) | 23.1590525837586 |

| 23 | 0.03 | =D24-(D24*B25) | 22.4642810062459 |

According to those calculations, there are 22.4 gallons left in the barrel, but this assumes that the alcohol percentage stays the same as it started.

The actual final proof is around 140 (70% ABV), so the 14 gallons that Wheately reports are equivalent to about 17.2 gallons at the original proof of 114 (57% ABV). That's a lot closer to the calculated number.

Wheately filled me in on some other practical factors for the math discrepancy.

“We have done a lot of proprietary work to determine the real proof drop while the barrels are aging so I wouldn’t want to reveal all our info…. (but)

While processing such small batches you get quite a bit of loss during the bottling process during the filtration process.

Also, during the course of 23 years there tends to be other factors such as leaks that increase the loss and are difficult to put numbers to.

A typical/perfect 23 year old barrel of wheated bourbon should yield about 14 wine gallons with about a 1-2 gallon loss during bottling which gets it down to 12-13 wine gallons recovered.”

So when you're paying for a bottle of Pappy Van Winkle 23 even at non-surge pricing, you're not just paying for the raw materials used to make and the time spent to age what's in that bottle, you're also paying for the raw materials and aging of 39 gallons of bourbon that evaporated before it got to the bottling facility, and a total of nearly 80% of the original juice that didn't make it into the bottle.