Last week I visited my 50th distillery/blending house at the Isle of Jura. What made it extra special is that we hit it at 1:30 in the morning.

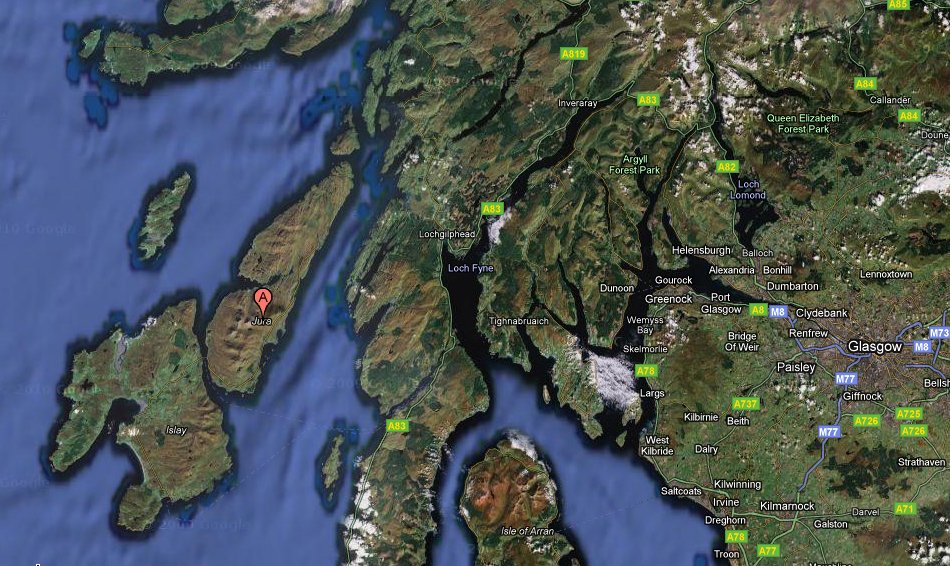

Though the Isle of Jura is closer to mainland Scotland than Islay, to reach it you take either a plane or ferry to Islay then another quick ferry to Jura. (Jura is the red dot on the map below. Islay is the island to its left.)

(Map produced using Google Maps.)

Jura has far fewer inhabitants than Islay- I think around 200 compared with Islay's 3500- and just one distillery compared with Islay's eight. We arrived on the island after a drive and boat trip, then had time for dinner and a visit to the pub.

It was after we left the pub (they kicked us out at 1:15AM) that we noticed the lights were on in the distillery. "Do you want to see it now?" asked Willie Tait, Jura's Master Distiller, to the last two journalists standing.

"Um, yeah!" we said, and in we went.

(Late night in the distillery.)

The next morning we gathered up everybody for the real tour. Tait calls Jura "A Highland whisky made on an island," which is short for "unpeated." Islay/island whiskies are known for their smoky flavor, which comes from drying sprouted barley with peat smoke.

In the olden days when the first Jura distillery was built back in 1810, the whisky would have been heavily peated as the barley would have been dried locally.

Jura had no distillery for a long time- the current one opened in 1963- and by then everything had changed. Most barley is dried in large commercial facilities then shipped to distilleries. Each distillery can specify the level of peatiness of their malted barley (in phenolic content), and Jura for the most part specifies none at all.

(Malted barley ready for use at Jura.)

The barley is brought to the distillery, milled to break it up, then washed with hot water to release sugars, fermented, and distilled.

The stills on Jura are quite tall- 28 feet- and this produces a spirit that is very light in body, emphasizing the high esther notes ("pear drops") in the whisky.

(Tall stills at Jura.)

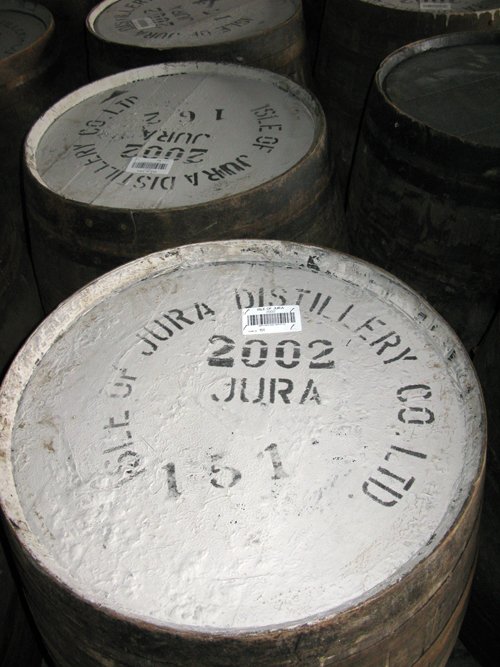

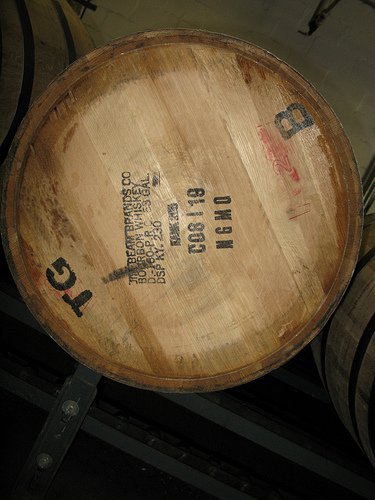

Jura is aged in a few kinds of wood. Much of it is what Tait called "American oak." These casks are ex-bourbon barrels that also were used to age scotch and have been rebuilt into hogshead sized barrels that are a little bigger than the bourbon ones. Unlike "ex-bourbon" barrels that are also used on Jura, the American oak barrels aren't still soaking with bourbon and don't add as much character to the spirit- they just let it age slowly without flavoring it so dramatically. Jura also uses ex-sherry butts in smaller amounts.

Tait emphasized that with Jura the point is to get the distillation just where you want it, then not mess around with the spirit too much in the barrel. (You'll see how this is the opposite of what happens at The Dalmore in another post.) Most Jura starts off in American oak then can be finished in other casks to nudge it a little in one direction or the other.

The main Jura bottlings are the 10 and 16 year-olds. The 10 is full of pear flavor and Tait says he would even recommend it served on the rocks as a pre-dinner aperitif. The 16 is more full-flavored and rich, striking a nice balance between friendly flavors and the depth that comes with aging.

Jura does use some peated barley in its production. The Superstition bottling uses 13% malted barley peated to 40ppm phenol, with the rest un-peated barley. Tait calls it a gentle introduction to peated whiskies. I call it tasty.

The last bottling, which is new to the US market, is the Prophecy. It was distilled in 1999 from all peated barley, and aged in some Limousin oak and Oloroso sherry along with the usual American oak and ex-bourbon casks. It's bottled at 46% and non-chill-filtered. So I guess that one is an island whisky made on an island.

Much more to come from my trip in later posts…