In yesterday's post in the Solid Liquids Project (project index here) I had expanded beyond dehydrating Campari into dehydrating other liqueurs, namely X-Rated Fusion Liqueur, Wild Turkey American Honey, Irish Mist, and Midori. These are all part of the Skyy Spirits portfolio.

In yesterday's post in the Solid Liquids Project (project index here) I had expanded beyond dehydrating Campari into dehydrating other liqueurs, namely X-Rated Fusion Liqueur, Wild Turkey American Honey, Irish Mist, and Midori. These are all part of the Skyy Spirits portfolio.

Of these four, only Midori crystallized like Campari had. I tried several methods to make the others crystallize but failed for the large part. I went over those in yesterday's post.

(Note: Before you get too deep into this, I just want to warn you that at this point I haven't figured out a solution to this problem and I welcome your suggestions.)

Nothing was working to make the others crystallize, but then inspiration hit.

Inspiration: What Do These Liqueurs Have in Common?

I realized that two of the liqueurs – Wild Turkey American Honey and Irish Mist – are sweetened with honey!

Furthermore, though I have no proof of this, I suspected that X Rated Fusion Liqueur may be sweetened with fruit juice.

Perhaps these other forms of sugar do not crystallize, or don't do so in the same way that cane sugar/sucrose does.

But first, I figured I should test the theory that X Rated Fusion Liqueur does not crystallize in the same way that known fruit juice-sweetened liqueurs do not crystallize. I placed X Rated Fusion, Hypnotiq, and Courvoisier Rose into cupcake cups and baked them at 140F for about 36 hours.

Courvoisier Rose came the closest to crystallizing, being a dense and sticky puck of liqueur. The other two were just gooey.

Though this doesn't necessarily prove anything, it's a clue that fruit juice-sweetened liqueurs don't crystallize the same way cane sugar/sucrose-sweetened liqueurs do.

A Further Test

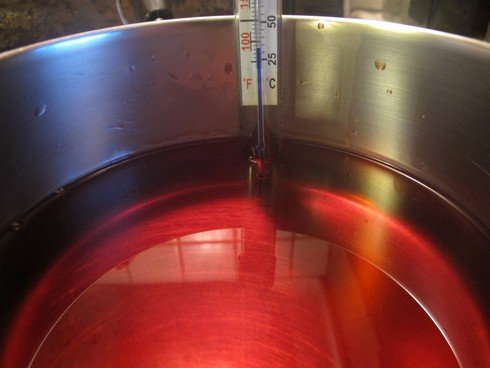

While I was performing these experiments, I learned of the Stovetop Crystallization Method previously discussed. That method seems pretty foolproof, so I decided to test it on both X Rated Fusion Liqueur and on Wild Turkey American Honey just to be sure they don't crystallize even at high candying temperatures.

X Rated Fusion turned from pink to brown to black.

And even at high temperatures, it just formed a thick molasses-like candy syrup that would solidify as soon as you removed it from heat. These sugar pucks do not make good sugar crystals even after you crush them. The resulting sugar/powder is just as sticky as a syrupy liquid.

Wild Turkey American Honey performed similarly, except it does not turn black. It's more like a caramel at the end.

Again though this doesn't prove anything, it may be a clue as to which type of liqueurs do and do not form crystals when you dehydrate them.

In the next set of experiments, I'll look at a couple other honey liqueurs to see if they similarly do not crystallize while other liqueurs do.

Then I'll try to overcome this obstactle.

The Solid Liquids Project index is at this link.