Though vermouth as an essential ingredient in cocktails, I never gave much though to its production, figuring it was just a simple infusion of herbs in fortified wine. It turns out there is a lot more to it than that.

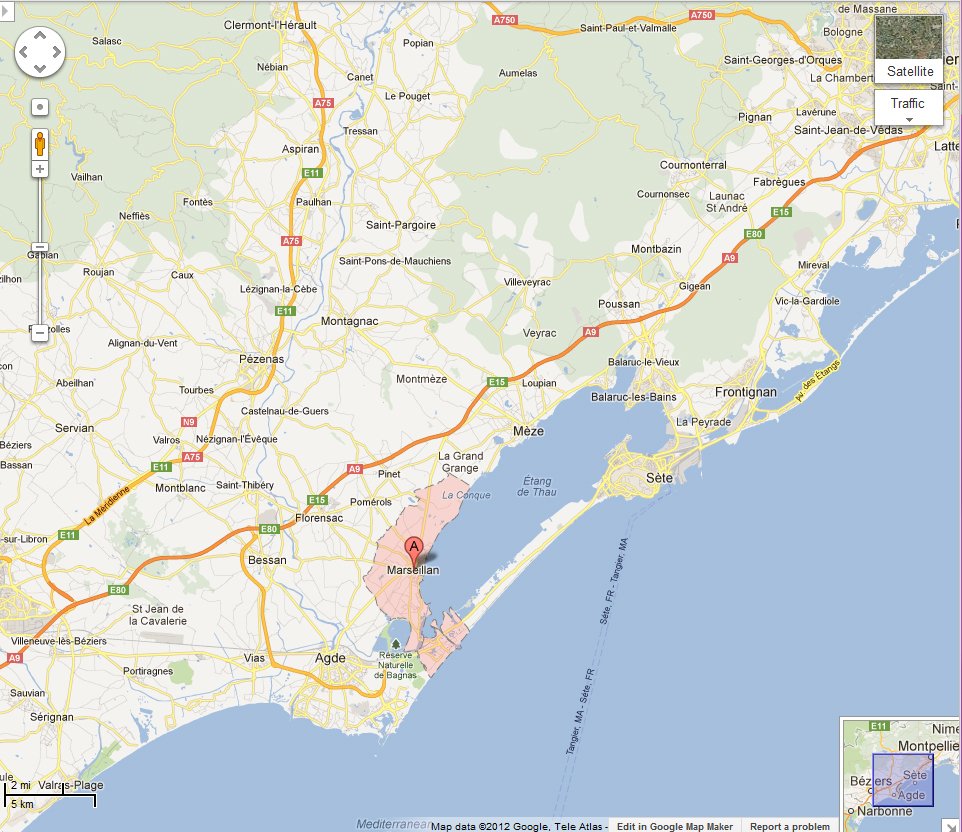

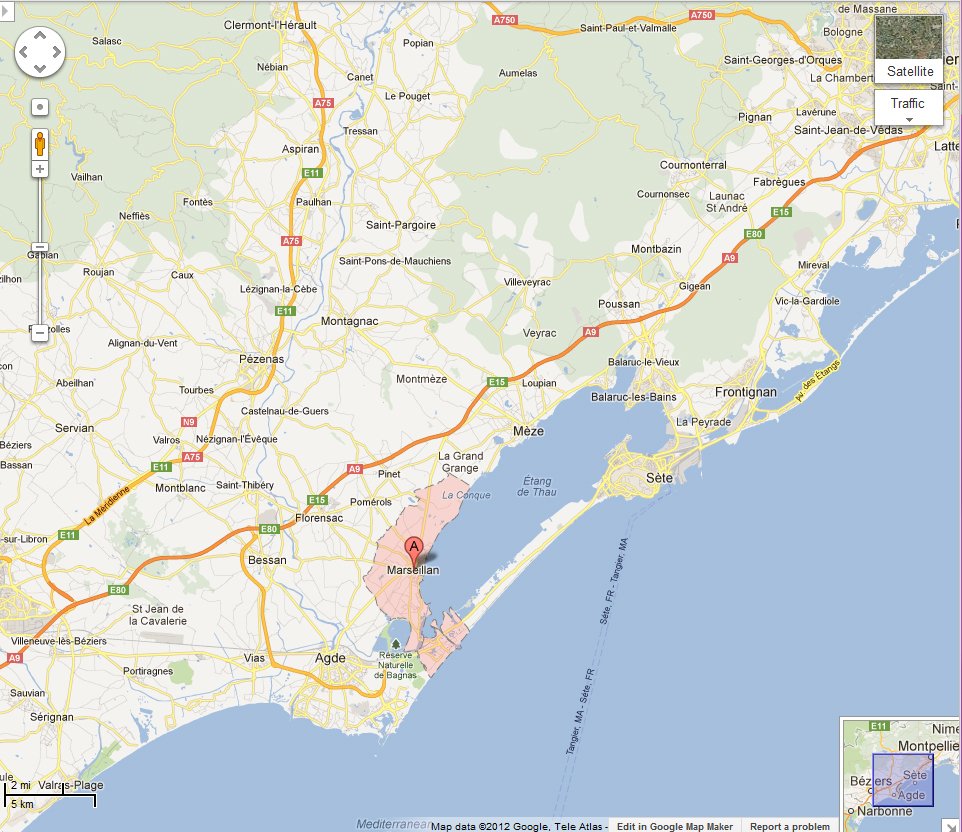

This June I visited Marseillan, France, the home of Noilly Prat vermouth. There, it is pronounced "No-ah-lee Pra" or "No-ah-lee Praht".

This brand is considered the first commercial dry-style vermouth in the world, dating to 1813. The recipe was created then in Marseilles by Joseph Noilly. His son moved production to Marseillan in 1850 and his when his grandson-in-law joined the company it became Noilly Prat. In the early 1970s Noilly Prat was purchased by Martini & Rossi, and that company was purchased by Bacardi in the early 1990s.

Marseillan is a small fishing town in the Southeast of France, located near the vineyards of the Languedoc region, which abut the oyster farms separated from the Mediterranean Sea by a small strip of land. Not coincidentally, Noilly Prat Dry is served with oysters in the region, and oysters are served everywhere.

Vermouth is a fortified, aromatized wine. So let's get into how it is made.

The Wines in Noilly Prat

Three kinds of wine go into Noilly Prat Original Dry: Picpoul, Clairette, and muscat for the sweetening mistelle. Many of the wines are grown next to the ocean Mediterranean Sea, adjacent to the oyster farms. What grows together, goes together.

Those rows of things in the water beyond the vines are oyster tables

Picpoul is an AOC wine in the area, smelling and tasting citrusy and a little tart. It too pairs with the local seafood. It makes up 60 percent of the wine in Noilly Prat.

Clairette, making up the other 40% of the wine blend in Noilly Prat, is less acidic than picpoul. It is fruitier and less citrusy than picpoul.

These wines are usually harvested in September. Noilly Prat doesn't own the vineyards but purchases them from local cooperatives. In fact, they buy wines, not the grapes themselves. The wines are 12.5 to 14 percent alcohol by volume, and not aged in oak (yet).

The Mistelle is the sweetening agent for Noilly Prat. Is is made from the partially fermented muscat grape juice. Fermentation is stopped by adding spirit (neutral sugar beet spirit) before it fully completes, leaving the wine very sweet at around 100 grams per liter sugar content.

The room where the mistelle ages is filled with huge vats. It dates back to around 1850. The vats were so big they were installed first, and then the building was built around them. In this room the mistelle ages for a year.

Aging The Wines

In the olden days,wines would have been sent out on boats to their destinations, aging in barrels along the way. However with faster transportation the wine was not the same. So Noilly Prat began replicating the aging step with their unique method called L'Enclos.

Behind the front building at the Maison of Noilly Prat is a courtyard, and in this courtyard are 2,000 barrels where the picpoul and clairette wines age separately outdoors for a full year, oxidizing and taking on aspects of the salty sea air.

The barrels are watered regularly to minimize evaporation of the wine

Before aging these wines are fortified (with neutral sugar beet distillate) to 18 percent for picpoul and 16 percent for the clairette. We sampled wines aged about 6 months from the barrels – the picpoul wine still tasted very citrusy (apparently picpoul means something like "lip stinger") but took on an oxidized smell that reminded me of flan. The Clairette also tasted oxidized and quite salty, reminded me a little bit of manzanilla sherry.

All the wine for Noilly Prat ages in this one courtyard, though they have more room in other courtyards should we start drinking more vermouth.

The barrels used are all more than 30 years old, some of them more than 100 years old. I believe they said they purchase them from scotch whisky distilleries, but they didn't look to me like ex-bourbon barrels but ex-sherry butts and ex-port pipes as they were all larger than the typical 55 gallon barrels of bourbon.

As the barrels are so old (thus quite neutral and won't lend woody characteristics to the wine), there is a cooperage repair shop on site, located in a building where they used to distill absinthe.

In the cooperage. That staircase? Designed by a guy named Eiffel.

Infusing the Vermouth, and One Last Aging

Indoors in the Vermoutherie, the aged wines and aged mistelle are transferred here. Another distillate now comes into the equation: Lemon peels and raspberries are macerated in neutral sugar beet spirit for one week and then redistilled in a pot still to 76 percent alcohol. This flavored distillate is then used to further fortify the wine.

Pot still of the same kind used to make the lemon-raspberry flavored distillate.

In 2050 liter oval pine wood vats, the aged picpoul, clairette, and mistelle, plus the flavored distillate, are infused with the custom blend of herbs and spices for three weeks.

Every day during this period a person stirs the macerating wine for two minutes with a special sickle-shaped tool for the purpose.

Stirring the macerating herbs

After maceration, the vermouth is filtered in a big rotary filter to remove the herb particles. The vermouth is then further aged 3 more months in the same sized vats that hold the mistelle.

In tomorrow's post, I'll discuss the different herbs and spices (plus a few other production differences) used in Noilly Prat Original Dry, Rouge, and Ambre.

But I hope this post makes it clear that producing vermouth (at least this vermouth) is no simple business. I no longer just twist open a bottle and dump it into my cocktails- I now pour a bit into a glass with a single ice cube and savor it on its own first. Props.

Next Up: Read about the differences between Noilly Prat Original Dry, Rouge, and Ambre.

Then read about the new Extra Dry on the US market in summer 2013 and the difference between Original Dry and Extra Dry.