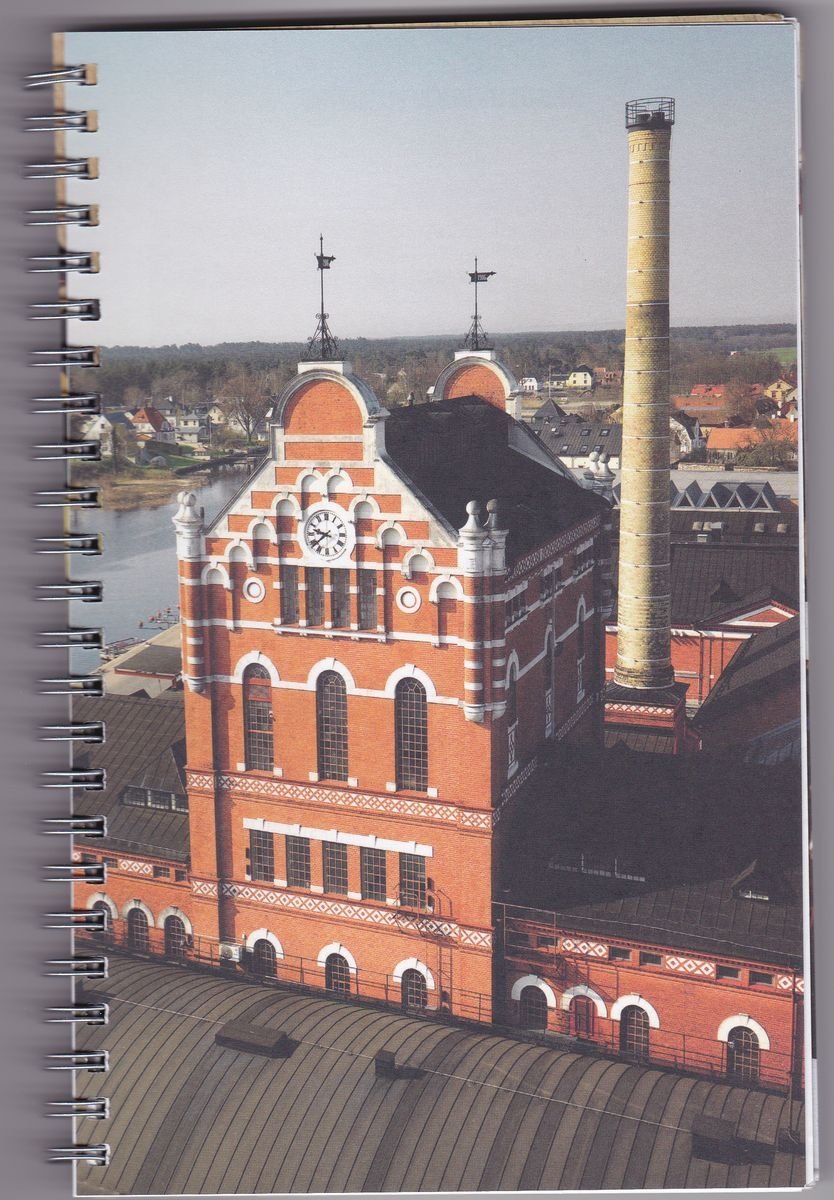

I've been to the Beam distillery three times now. I wrote about my first visit in 2008 here, with an additional post about the bottling line. Then I stopped by for another brief visit in 2012 where I got a preview of some of the outdoor displays as part of the new visitors' center.

In early 2013, I revisited the Jim Beam distillery during my visit for the Bourbon Classic, held in Louisville. In 2014 the Bourbon Classic will be held on January 31 and February 1.

This time, the new visitors' center, called the Jim Beam American Stillhouse, was fully operational and we went on a really cool tour. I'm not sure if this is the same tour offered to everyone or not, but it quite likely was.

As I learned on previous visits, the actual distillery is quite industrial and not super pretty, so they built a new microdistillery where they do small batch versions of bourbon. It makes 1 barrel batches at a time.

They took us through a room where we'd put a scoop of grains into the cooker and saw the small column still, so we were able to see the whole production process though not the actual equipment used to produce Beam for the most part.

But anyway, here are some things I learned:

- The mash is 6% ABV after fermentation

- They use 41% sour mash. Other distilleries I visited used roughly 33%. I do not know what the difference that makes in the flavor of the final bourbon.

- The cooked mash goes through over a mile of pipes before fermentation to chill it without using tons of electricity.

- The fermentation process takes 3 days.

- Their fermenters are closed-top rather than open

- The big column still has 23 plates. It is 5 feet wide and 5 storeys tall.

- They distill to 125 proof in the column still, then to 135 proof in the doubler.

- They fill 300,000 barrels every year and have 1.8 million barrels in storage.

- They give their barrels a #4 char

- The whiskey goes into barrels at 125 proof, which is the maximum

- There are 72 warehouses where they age whiskey, 28 of them are on-site at the distillery

While this post focuses on production, between the microdistillery, outdoor displays, visitors' center, and new restaurant on site, the Jim Beam distillery has gone from an industrial distillery to a great tourist attraction.